Leave the Harder Work to Our Tools with the HOMIE Excavator

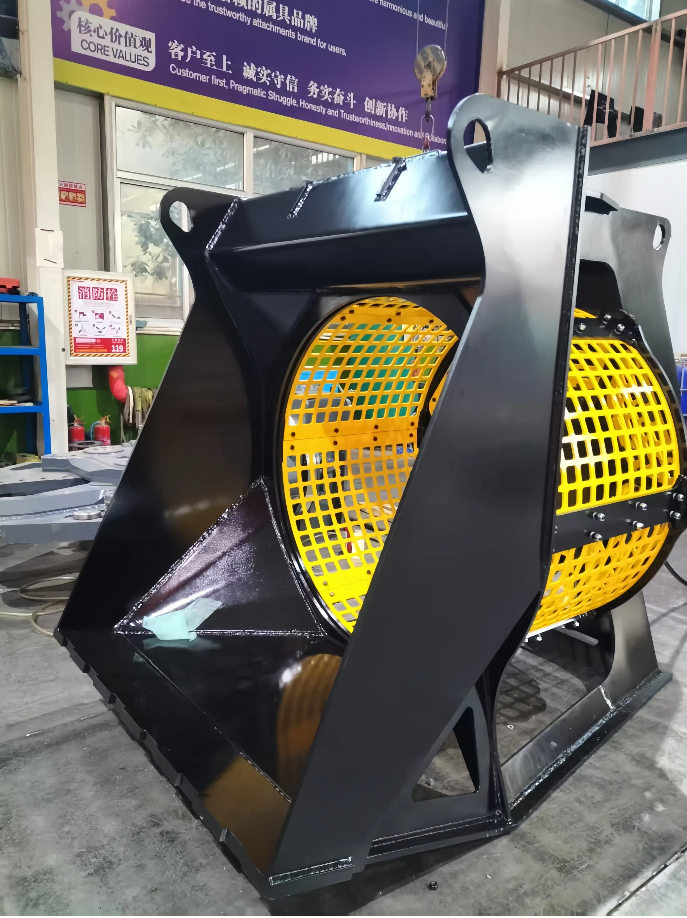

Hydraulic Rotary Screening Bucket

Struggling with screen clogging, uneven material separation, or poor compatibility across scenarios? The HOMIE Hydraulic Rotary Screening Bucket (Model MB-S) is designed for 3-35 ton excavators, and also fits skid steer loaders, wheel loaders, and backhoe loaders. Whether screening topsoil, grading quarry stones, remediating contaminated soil, or handling demolition waste, it separates materials efficiently, reducing crushing time by up to 60% and simplifying resource recycling!

1. 5 Core Features for Max Screening Efficiency

1. Clog-Resistant Screens + Low Noise – Smooth Operation

Specialized screen hole design minimizes material clogging, eliminating frequent shutdowns for cleaning. Fully hydraulic drive ensures low noise, making it suitable for urban/residential areas – balancing efficiency and environmental compliance.

2. Simple Structure + Easy Maintenance – User-Friendly

No complex mechanisms, so daily inspection and maintenance are straightforward. Operation logic aligns with excavator controls – experienced operators master it in 30 minutes, no extra training needed, cutting labor costs.

3. Durable Screens + Customizable 10-80mm Mesh – Multi-Material Fit

High-wear dedicated screens last 3x longer than ordinary screens. Mesh size is customizable (10-80mm): 10mm for fine soil, 50mm for gravel – precisely matching different material needs, no equipment swaps required.

4. Easy Component Replacement – Reduced Wear

Key components are designed for quick replacement, minimizing disassembly time and machine wear. For example, a worn screen can be replaced by one person in 1 hour – no project delays.

5. Multi-Equipment Compatibility – One Bucket for Multiple Machines

Fits not only 3-35 ton excavators but also skid steer loaders, wheel loaders, and backhoe loaders. One screening bucket covers multiple machines, reducing equipment investment costs.

2. 6 Core Applications – Full-Coverage Material Screening

1. Primary Demolition Waste Screening

Separates concrete chunks, bricks, and impurities from demolition waste – recovers reusable aggregates, reduces landfill volume, and meets environmental standards.

2. Rock Recycling

Cleans soil and debris from cobblestones and natural stones – screened stones are reused for road paving or landscaping, enabling resource circulation.

3. Quarry Grading

Precisely grades ores into sizes (e.g., 20mm, 50mm, 80mm) – no secondary screening needed, directly matching downstream processing requirements.

4. Coal Industry Separation

Separates lump coal from pulverized coal and supports coal washing processes – improves coal purity for different combustion scenarios.

5. Chemical & Mineral Processing

Grades large/small mineral lumps and separates powdery impurities – ensures mineral raw material purity, boosting subsequent processing efficiency.

6. Contaminated Soil Remediation/Beach Cleanup

Screens harmful substances (e.g., gravel, garbage) from contaminated soil or cleans sand and debris from beaches – aiding ecological restoration projects.

3. Why Choose HOMIE? 4 Reliable Reasons

1. Industry Expertise – Solves Real Screening Pain Points

Years of experience in excavator attachments – understands job site frustrations (clogging, maintenance hassle) – product design optimized for actual working conditions.

2. Strict Quality Control – Dependable Performance

Every screening bucket undergoes multiple tests (clogging resistance, wear resistance) before delivery – ensures stable operation under heavy loads and multi-material scenarios, no "quick failures."

3. Customer-Centric Service – Responsive Support

Whether for custom screens, equipment compatibility, or after-sales repair, the professional team responds within 24 hours. For overseas customers, solutions are provided within 48 hours – no project disruptions.

4. Continuous Innovation – Leading Technology

Constantly upgrades screening structures (e.g., optimizing screen hole angle, enhancing hydraulic synchronization) – ensures 20% higher efficiency than competitors, keeping customers ahead with advanced tools.

4. Conclusion: Save Time on Screening – Choose Model MB-S!

The HOMIE Hydraulic Rotary Screening Bucket (Model MB-S) is not a "single-function screen" but a "material grading solution" for multi-scenarios and multi-equipment. Clog-resistant screens = less downtime, customizable mesh = multi-material fit, multi-equipment compatibility = cost savings, plus 60% crushing time reduction – ideal for resource recycling and project material separation.

Choose HOMIE, turn your excavator (or other machines) into a "high-efficiency screener" – boost project efficiency and support environmental sustainability, all in one!

Post time: Dec-01-2025